HOW REA INTEGRATES SUSTAINABILITY IN ITS CORE PRACTICES THROUGH CERTIFICATION

Sustainability certification provides third party verification that a company is operating in accordance with national and international standards.

Further, it encourages companies to improve their policies and practices by establishing higher premia for certified products. Standards are embodied in various certification schemes, specifically the Roundtable on Sustainable Palm Oil (RSPO), Indonesian Sustainable Palm Oil (ISPO) and International Sustainability and Carbon Certification (ISCC). These schemes focus on minimising deforestation, transparency feedstock supply chains, human rights and safety, and measurement of GHG emissions. The group aims to achieve and maintain certification under these internationally recognised schemes for all of its plantations and mills.

The sustainability department is responsible for monitoring the sustainability of all of the group’s estates and mills and has expanded as new estates have been developed. The department is not just responsible for ensuring that the group complies with the standards of each certification scheme, but also provides regular in-house training on sustainability-related issues in an effort to ingrain sustainable working practices into the everyday operations of the group. The sustainability team also works with the heads of each department to develop key performance indicators for the workforce and sustainability agreements for third party contractors that are in line with our sustainability commitments.

Multiple certification schemes and standards focused on palm oil production exist, such as the Roundtable on Sustainable Palm Oil (RSPO) standard and the Indonesian Sustainable Palm Oil (ISPO) standard. Further, general schemes and standards exist, such as the International Sustainability and Carbon Certification (ISCC) scheme, focused on zero-deforestation and transparent feedstock supply chains and measurement of greenhouse gas emissions. The group remains committed to ensuring that all of its plantations and mills achieve and maintain, amongst others, RSPO, ISPO and ISCC certification.

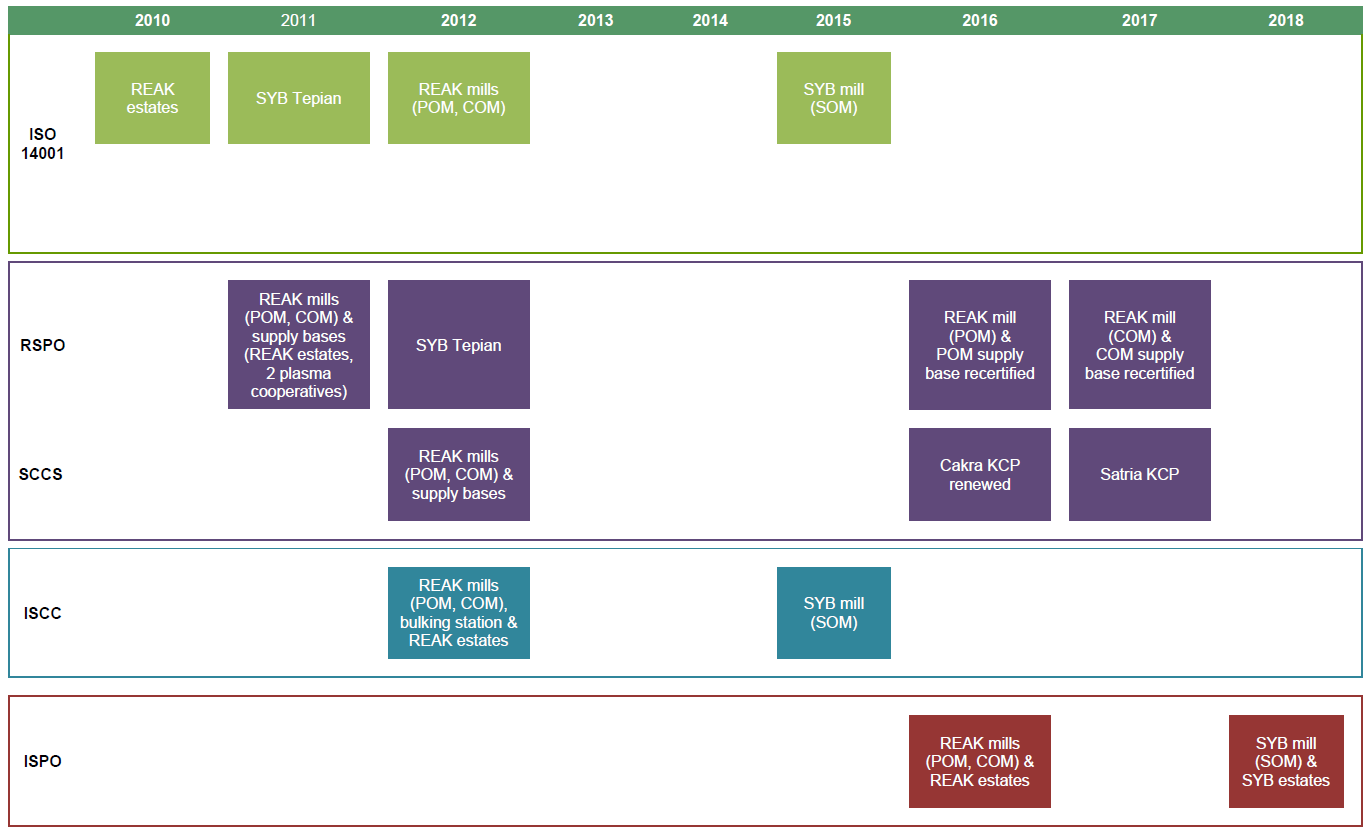

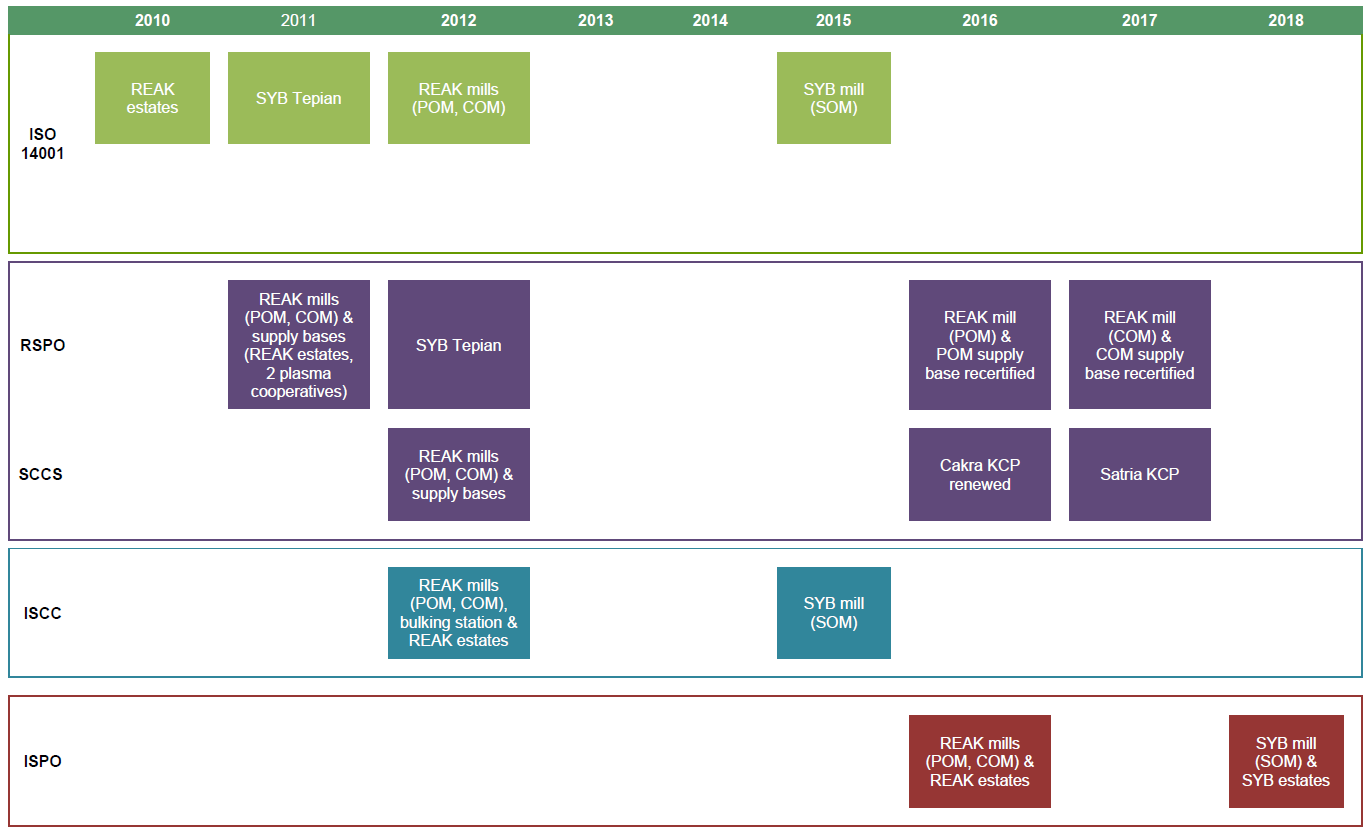

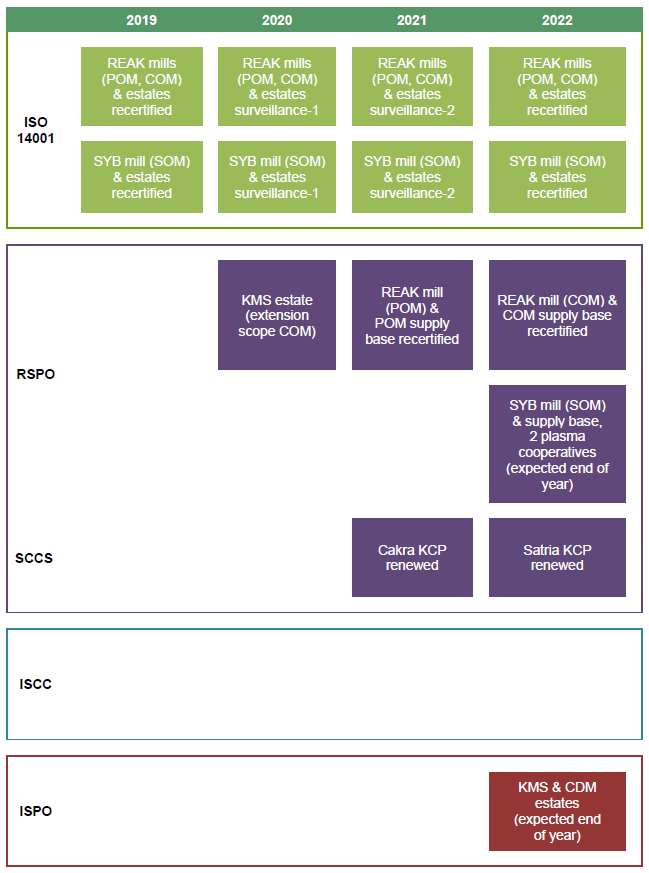

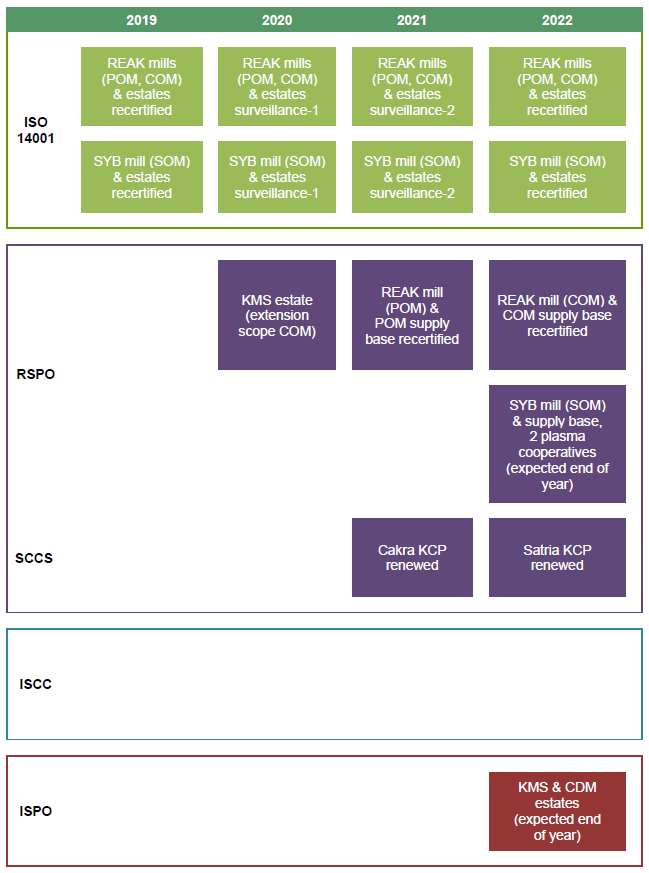

Sustainability milestones

Roundtable on Sustainable Palm Oil (RSPO)

The group has been a member of RSPO since 2007. RSPO is a multi-stakeholder organisation that has developed a standard to promote the sustainable production ion of palm oil. The RSPO standard is voluntary and consists of a set of Principles and Criteria designed so that entities can be audited against RSPO Supply Chain Certification Standard.

The group’s two oldest mills POM and COM, and their supply chains were first certified in 2011. The supply chain for COM includes the group’s most recently matured estate, KMS, which attained RSPO certification in 2020 after a two year independent audit process. Surveillance audits are conducted annually to ensure continuing compliance and recertification audits take place every five years. In 2021, the surveillance and recertification audits were conducted via a combination of remote and onsite audits due to COVID travel restrictions. The fourth annual surveillance audit for COM was successfully completed, securing renewal of its Palm Trace licence. The five-yearly recertification audits of POM, the COM kernel crushing plant (KCP) and their supply chains, together with the group’s downstream bulking station, were also completed in 2021 with certification successfully renewed until 2026.

|

As previously reported, the RSPO certification for the group’s third oil mill, SOM, requires resolution of an RSPO compensation liability in respect of two small land areas within SYB that were cleared in 2008 prior to changes in the regulations that required conducting HCV assessments. The group’s proposal in respect of some 129 hectares of land at Satria estate and the final HCV compensation liability in respect of 44 hectares at SYB’s Tepian estate, that were excised from the supply base to each of SOM and POM in 2019, were both approved during 2021. For each liability, the group has developed a concept note for a conservation and rehabilitation programme in accordance with the RSPO’s Remediation and Compensation Procedure. The concept notes remain subject to review by the RSPO and, once approved, SOM can be audited to secure certification and the Tepian area will be reinstated within the POM certified supply base. Certification of SOM’s KCP remains unaffected by the ongoing compensation liability cases and successfully completed the annual RSPO surveillance audit in 2021. The social impact assessment (SIA) required to be conducted by third party consultants in respect of 959 hectares cleared at CDM prior to conducting an HCV assessment was conducted in March 2022. A compensation plan has already been agreed in principle with RSPO and payments will be settled over several years as part of a time-bound plan which was agreed with RSPO for RSPO certification of CDM by 2023. RSPO has also reviewed certain incidences of land clearing prior to HCV assessments in respect of two plasma cooperatives that were reported pursuant to a land use change assessment (LUCA) in 2019. In March 2021, following a review of the additional supporting materials provided by the group and the local communities, it was agreed that the group has no social liability in respect of the areas in question. However, the RSPO has determined that the group has conservation related liabilities in respect of 624 hectares and environmental remediation liabilities in respect of 39 hectares. Accordingly, the group is now developing relative concept notes for RSPO approval. The liabilities in respect of CDM and the plasma cooperatives are not material. |

|---|

RSPO Supply Chain Certification

This certification allows the group to sell its RSPO certified CPO and CPKO to buyers committed to purchasing RSPO certified sustainable palm oil (CSPO).

If it can be proven that a specific batch of CPO or CPKO originated from an RSPO certified estate and mill, it can be sold as identity preserved or segregated certified sustainable CPO or CPKO. If the certified product mixes with non-certified products in the supply chain, then it can be sold as certified sustainable CPO or CPKO using a mass balance system. This requires records to be kept that demonstrate that the volume of CPO and CPKO sold as sustainable palm oil does not exceed the amount produced by the upstream RSPO certified mills over a specified time period.

REA operates two KCPs attached to the Cakra and Satria oil mills. These KCPs crush all of the palm kernels (PK) produced at the group’s 3 mills. In 2021 the group KCPs crushed a total of 44,683 tonnes of PK, of which 24,252 tonnes (54%) were from RSPO certified sources and produced by the processing of 603,642 tonnes of certified FFB from group owned plantations. The remaining 29,832 tonnes (46%) of PK crushed in 2021 originated from the processing of 329,478 tonnes of uncertified FFB, of which 121,586 tonnes were supplied from uncertified group plantations, 149,116 tonnes from independent smallholders, 58,768 tonnes from associate smallholders (PPMD), and 8 tonnes from corporate outgrowers. REA currently does not crush PK from any other sources.

Summary of 2021 RSPO supply chain data:

| Raw material supplied | FFB processed (tonnes) | PK crushed (tonnes) | KCP Cakra Processed (tonnes) | KCP Satria Processed (tonnes) | Uncertified PK sold to third parties | |||

| Certified | Uncertified | Certified | Uncertified | Certified | Uncertified | (tonnes) | ||

| Certified FFB: | ||||||||

| Own plantations: | 603,642 | 24,252 | 5,774 | 22,877 | – | 1,374 | 5,675 | – |

| Subtotal | 603,642 | 24,252 | 5,774 | 22,877 | – | 1,374 | 5,675 | – |

| Uncertified FFB: | ||||||||

| Own plantations | 121,586 | – | 5,908 | – | 2,196 | – | 2,815 | 389 |

| Independent smallholder | 149,116 | – | 7,208 | – | 3,461 | – | 2,876 | 377 |

| Associate smallholder | 58,768 | – | 2,836 | – | 1,532 | – | 961 | 150 |

| Corporate outgrower | 8 | – | 0 | – | – | – | – | – |

| Subtotal | 329,478 | – | 15,953 | – | 7,189 | – | 6,652 | 916 |

| Total | 933,119 | 24,252 | 21,728 | 22,877 | 7,189 | 1,374 | 12,327 | 916 |

For more detailed information on the traceability data at each crusher to plantation, click here.

At present, the mass balance system is preferable for REA because it enables the group to continue to purchase FFB from independent smallholders who are not yet RSPO certified.

By continuing to engage with these smallholders, the group can assist them in improving their farming practices, which should enable them to obtain RSPO certification in the future. If REA had chosen to produce segregated CSPO, REA would have had to exclude these smallholders from its supply chain. For many of these smallholders, this would prevent them from obtaining income from their land due to there being very few alternative palm oil mills near enough to process their FFB. More information about how REA is working with smallholders to improve their practices can be found here.

International Sustainability and Carbon Certification (ISCC)

CPO produced from mills certified under the voluntary ISCC scheme may be sold for biofuel under the European Union Renewable Energy Directive (EU RED). Following recertification audits, certificates for each of the three mills and the bulking station were renewed in 2021. Recertification audits for the current year took place in February 2022 with zero non-compliances recorded and renewal certificates for the 3 mills and bulking station were issued in March 2022.

Certified sales

The group uses the RSPO PalmTrace system, developed and managed by UTZ, for certifying transfers of oil palm products from mills to refineries. RSPO PalmTrace also offers a marketplace and the option to register off market deals through a “Book and Claim” system for RSPO credits; such registration confirms that the applicable CPO and CPKO was produced by an RSPO certified company.

Each sale of CPO and CPKO can be made with only one certificate, so the group must decide which certification should apply to each sale. Most CPO is sold with ISCC certification because, in the context of the overall CPO market, buyers offer higher premia for ISCC certified CPO than for RSPO certified CPO. There is no market for ISCC-certified CPKO, but as demand for RSPO-certified CPKO increases, there is a consequential increase in premia. Where CPO and CPKO cannot be sold with ISCC or RSPO certification, available CPO and CPKO sustainability credits are sold through the PalmTrace system or off market to specific buyers.

2021 sales of CPO and CPKO are shown below:

| CPO | CPKO | |||

| tonnes | % | tonnes | % | |

| RSPO sales | – | – | 8,279 | 43.2 |

| RSPO credits | 13,183 | 5.9 | – | – |

| ISCC | 116,137 | 51.8 | – | – |

| Other (not certified) | 95,008* | 42.4 | 10,873 | 56.8 |

| Total | 224,328 | 19,152 | ||

*

Includes some certified CPO production that was sold as uncertified or without any sustainability premium

Indonesian Sustainable Palm Oil (ISPO)

The ISPO standard is a policy adopted by the Ministry of Agriculture on behalf of the Indonesian Government and is mandatory for all oil palm companies operating in Indonesia. REA Kaltim’s estates and its two mills, POM and COM, first achieved ISPO certification in 2016 and have passed annual surveillance audits by the SGS Indonesian Certification Institute each year subsequently. The five-yearly ISPO recertification audits for POM and COM were completed in 2021 and their certificates successfully renewed until 2026. SOM and the SYB estates first obtained ISPO certification in 2018 and successfully completed their 4th annual surveillance audits in 2022. ISPO does not apply to immature or development estates.

Environment

ISO 14001 is the international standard for effective environmental management systems that supports organisations in the development and implementation of environmental policies and objectives. The group maintains ISO 14001 certification, which is subject to annual renewal, for all of the REA Kaltim and SYB estates and mills as well as the bulking station. The recertification audits for REA Kaltim and SYB were conducted in March 2022 with certification successfully renewed until early 2025.

The group’s mills are also rated annually under The Program for Pollution Control, Evaluation and Rating (PROPER). PROPER is an initiative of the Indonesian Government’s Environmental Impact Agency which seeks to mitigate risks of pollution and associated consequences. The group is rated at both provincial and national levels. A blue rating denotes that environmental management standards meet the regulatory requirements; a green rating denotes that that the company’s standards go beyond the standard regulatory requirements.

| Provincial | National | |

| POM | Green | Blue |

| COM | Green | Blue |

| SOM | Green | Blue |